Thin-wall Injection Molds

Beyond Thin: Injection Innovation at Its Finest

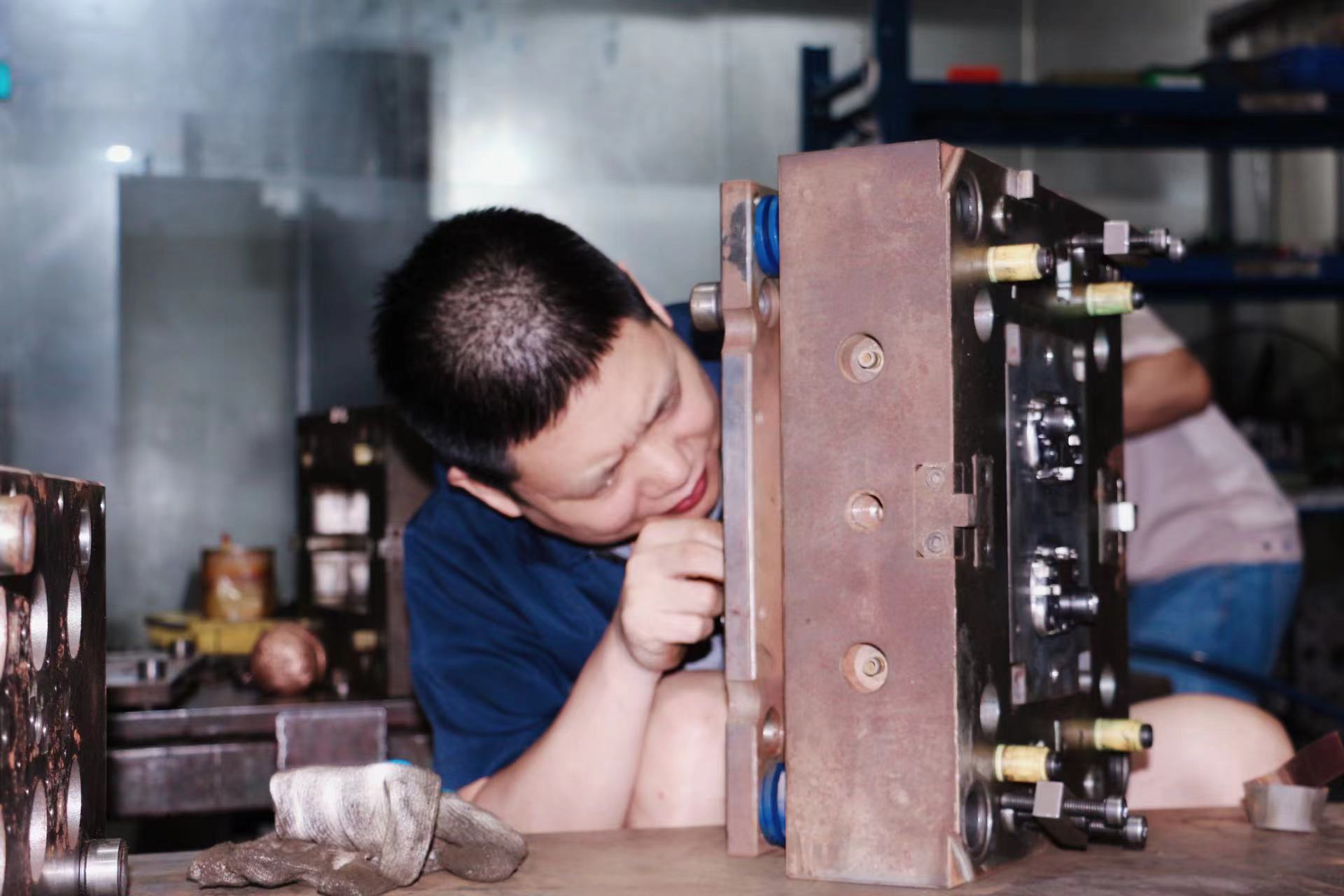

Thin wall molding boosts efficiency and speed. Our expert team ensures robust, precise parts despite reduced thickness.

Crafted Thin, Built to Win

Leveraging thin wall injection molding, we optimize production speed and material efficiency. Even with reduced thickness, our parts boast strength and impeccable precision. The key lies in our masterful mold design and meticulous construction, backed by a team with seasoned expertise, ensuring unparalleled excellence from conception to completion.

Harness the power of cutting-edge thin wall molding technology with our deep industry expertise. Our vast experience in designing, crafting, and implementing thin-wall injection molds empowers you to produce superior-quality thin wall products with heightened cost-effectiveness and efficiency. Here are some of the benefits:

1.Swift Production Cycle

Dramatically reduce cycle times; thin-wall molding achieves up to 50% faster fill times and slashes injection molding time by 60-70%, translating to significant cost savings.

2.Cost-Effective Material Use

The higher volume-to-material ratio of thin-walled parts lowers per-piece material expenses.

3.Enhanced Resource Efficiency

Combining reduced material costs, lighter shipping weights, and faster cycle times, our method ensures optimal resource utilization.

4.Eco-friendly Manufacturing

Thin-wall injection molding is uniquely suited for efficiently processing recycled plastics, fostering a more sustainable plastic production approach.

Applications of Thin Wall Injection Molding

The versatility of thin wall plastic injection molding finds its way into numerous sectors, enhancing efficiency and design:

1.Packaging Solutions

From food to consumer products, thin-wall molding offers robust and efficient plastic packaging solutions, streamlining storage and transport.

2.Medical Innovations

This method is instrumental in crafting medical devices, disposables, and their packaging, ensuring sterile, safe, and efficient solutions.

3.Electronics & Devices

Beyond protecting electronic components with durable housings, thin-wall molding is crucial for creating sleek components for cell phones and other handheld gadgets.

4.Consumer Goods

From everyday products to specialized items, thin-wall molding optimizes design, weight, and resilience, catering to evolving consumer needs.

5.Containers & Storage

Producing lightweight yet sturdy plastic containers and lids, thin-wall molding enablesefficient storage and portability.