Metal Injection Molding

Excellence at Scale

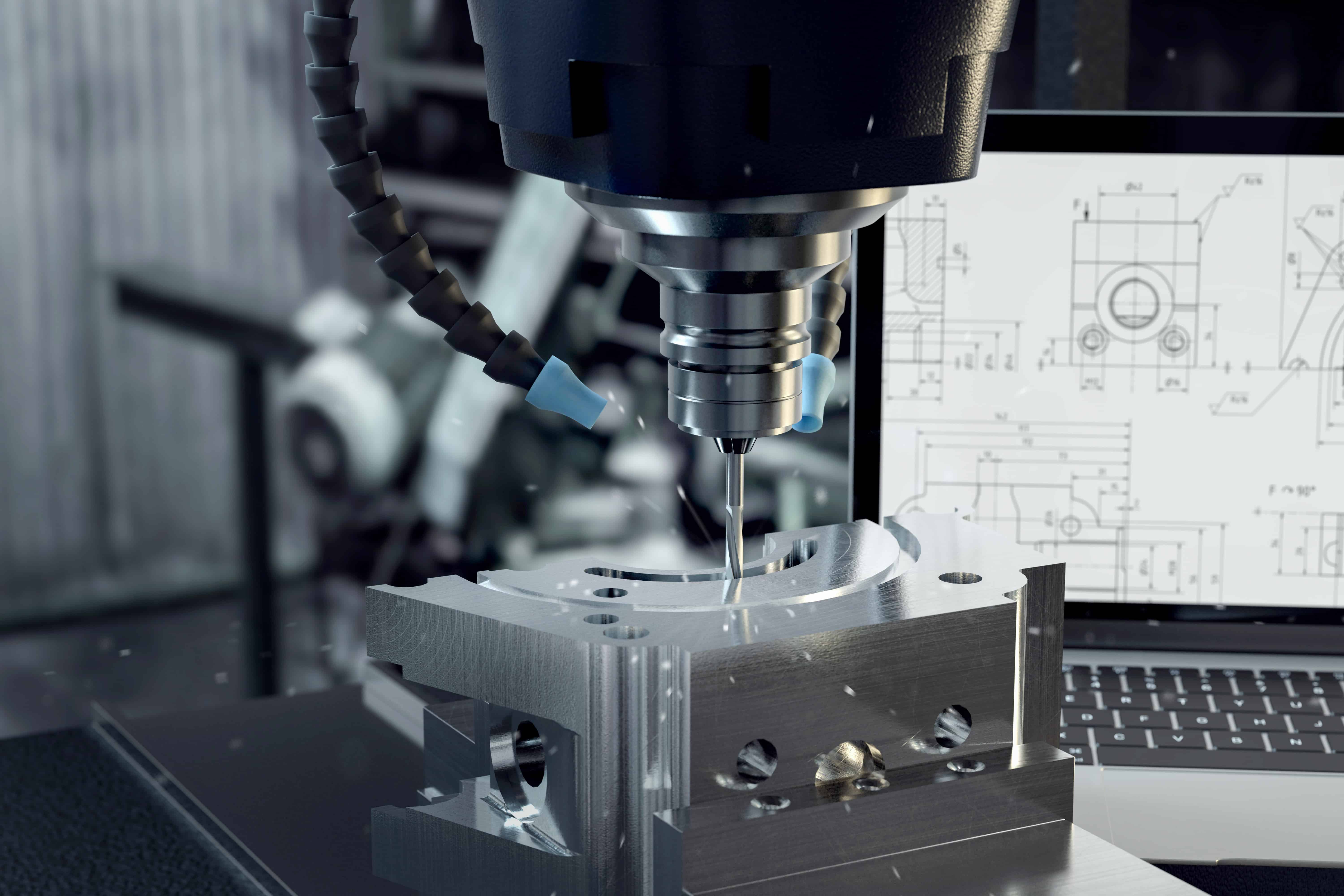

MIM combines the versatility of plastic injection molding with the strength of powdered metals, allowing for the efficient production of intricate, high-volume metal parts with exceptional precision. Ideal for crafting complex components, MIM ensures both cost-effectiveness and high performance.

Precision, Performance, Perfection

Metal Injection Molding offers precision, scalability, cost-efficiency and so much more for your metal product needs:

Complex Shapes: Our MIM process excels in crafting parts with intricate details, thin walls, and precise corners, all in a single step, allowing for complex geometries that other methods can’t achieve.

Assembly Simplification: We merge multiple components into a unified design, reducing assembly steps and costs. This also eliminates the need for expensive machining operations, further reducing costs.

Durable Materials & Flexibility: We utilize robust materials like stainless steel, making our MIM process ideal for high-temperature applications. Additionally, our material flexibility means we can adapt to different project needs, from softer metals to harder alloys.

Cost-Efficiency & Speed: Our MIM approach is tailored for high-volume production, ensuring rapid delivery of intricate parts at optimized costs. It’s a cost-effective solution, especially when scaled for large batches.

Design Freedom & Micro-Manufacturing: Our process offers unparalleled design freedom, allowing for the creation of unique and custom parts. Plus, our advanced machinery can manufacture micro-sized components with precision.

Scalable & Automated Manufacturing: Our automated manufacturing setup ensures that the MIM process is not only scalable but also repeatable, guaranteeing consistent quality across all parts.

Versatility: Our MIM expertise caters to diverse industries, from medical to aerospace, thanks to its adaptability in producing biocompatible and hardened components.

Precision & Performance: We consistently achieve critical tolerances, with the option for post-machining for added precision. Our parts are not only accurate but also high-performing, meeting the rigorous demands of various industries.

From medical devices to sporting goods to automotive parts, MIM is the best choice for mass production of intricate metal products, and we ensure that every part we produce meets the highest standards of quality and functionality.

Available Materials

Stainless Steel

316L

17-4 PH

17-4 H900

303

304

440C

420

Low-alloy Steel

4605

Fe-Ni50

Fe3Si

FeCo50

FeCoV

K1

K3

More

W-Ni-Fe

W-Ni-Cu

WC-Co

M2 (Tool Steel)