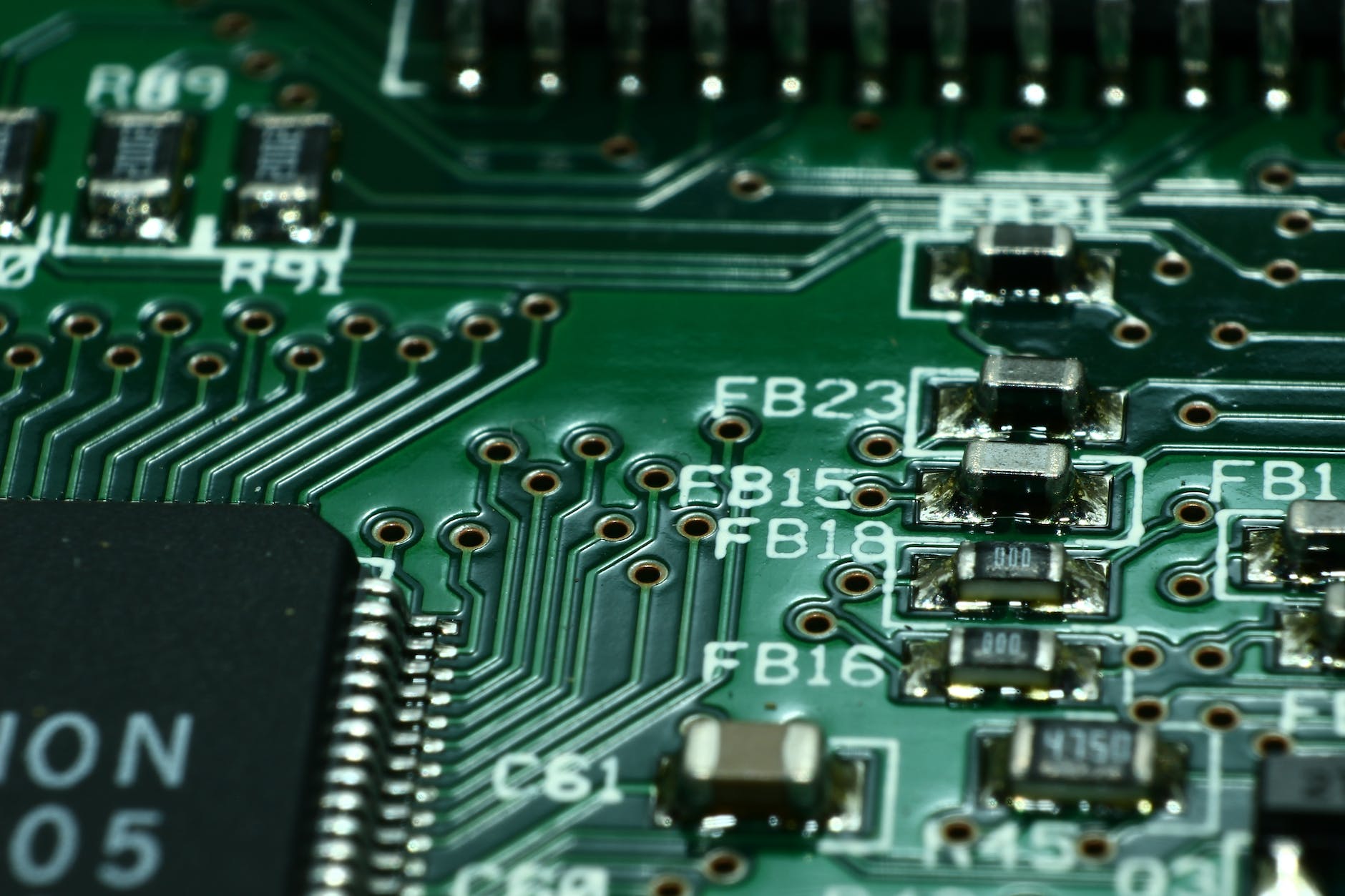

PCB Assembly

Where Every Connection Counts

With our advanced SMT and THT techniques, we handle both single-layer and multi-layer PCB assemblies. Our automated processes, inclusive of rigorous testing, cater to your specific requirements.

Crafting Connections, Assembling Excellence

Our PCBA process is a meticulous journey from precision solder application to comprehensive final testing, using a mix of SMT and THT as necessary for your product needs, more specifically:

•Single Side Mixed Assembly

•One Side SMT & One Side THT

•Double Side Mixed Assembly

For each workflows our commitment to excellence and attention to detail guarantees optimal functionality and reliability for every board we produce. Dive into our step-by-step process below to understand the expertise and dedication we bring to every project:

1.Precision Solder Paste Application: We initiate the PCB assembly by meticulously applying solder paste onto the board similar to screen-printing. Utilizing a precision-cut stainless-steel stencil, we guarantee that solder paste is accurately applied to designated component areas. Our state-of-the-art machinery ensures uniform distribution of the paste, setting the stage for optimal soldering.

2.Automated Component Placement (SMT): Once the solder paste is set, our advanced robotic systems take over, placing surface mount components on the PCB with precision. Our automation ensures both accuracy and consistency, eliminating potential human-induced errors.

3.Reflow Soldering: The prepared PCB then transitions through our specialized reflow oven. This process melts the solder, allowing it to solidify and create a robust bond. For dual-sided PCB Assembly, we meticulously handle each side with separate stenciling and reflow procedures.

4.Rigorous Quality Checks: After the reflow phase, each PCB undergoes a stringent inspection to validate component positioning and soldering integrity. We employ a combination of manual assessments, cutting-edge optical inspections, and X-ray evaluations to maintain our high-quality standards. Continuous checks throughout our workflow ensure prompt error identification and rectification.

5.Through-Hole Component Integration (THT): For PCB designs necessitating plated through-hole components, we utilize either expert manual soldering or advanced wave soldering techniques. This ensures that components, which transmit signals across the board, are securely anchored and soldered.

6.Comprehensive Final Testing: Concluding our process, each PCB is subjected to an exhaustive functional assessment, replicating its intended operational conditions. We vigilantly monitor the PCB’s electrical attributes, ensuring they adhere to predefined parameters.